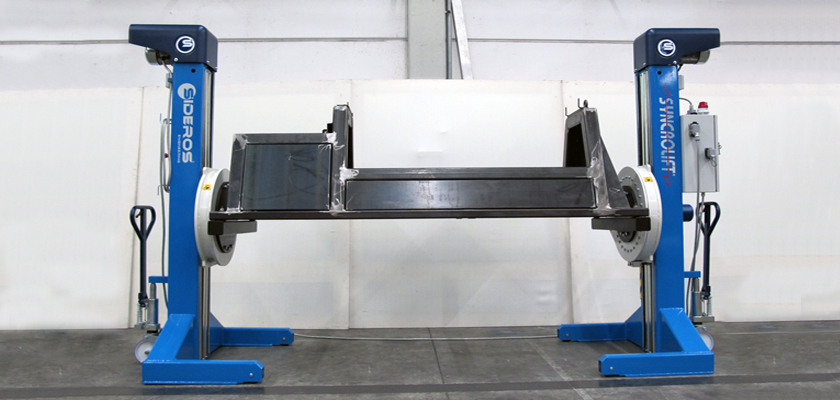

HEAD AND TAILSTOCK POSITIONERS

Capacities: from 4.000 kg (8,800 lb) to 15.000 kg (33,000 lb)

FEATURES:

Sideros Head and Tailstock Positioners can be used for a variety of parts and weldments. Typically a Head & Tailstock Welding Positioner is used for long rectangular shapes that must be supported from both ends.

Optional powered and manual mobile sub bases can be provided

on rails for varying part lengths allowing different length

weldments to be positioned with one station.

With a large rotation speed range all welding processes can be

accommodated, such as MIG, TIG, SAW and laser welding.

A typical configuration consists of a driven Headstock Positioner

with an Idler Tailstock. Dual Synchronized Headstocks can be used

for exceptionally long parts or parts that have torsion concerns.

Robotic versions to manual applications can be accommodated

depending on your specific needs.

FUNCTIONALITY:

Perfect synchronisation for best results. In the case of Headstock/Tailstock Elevating Positioners, the synchronization between Head and Tailstock utilizes AC variable frequency drives that provide dynamic synchronization during the elevation cycle, as well as absolute mechanical re-synchronization at full stroke, at either top or bottom limits.

The elevation axis uses two screw jacks for redundancy, coupled together and driven by a common motor.

MACHINES FEATURES:

• Suitable for long weldments positionning.

• Capacities range from 4.000 kg (5,500 lb) to 25.000 kg (44,000 lb).

• Low maintenance.

• Hand control pendant included in all models.

• Rotation speed control 50:1 AC.

• LCD display for the visualization of: messages, warnings, troubles and

graphic functioning.

• Absolute encoder performing with a high precision levels, rotations and

diagnostics.

• Ball screw jacks for high precision and duty cycles.

• Quote indication of the lifting height of each individual jack.

• Control of the load leveling with automatic re-alignment of the jacks not

in line.

HEAD AND TAILSTOCK POSITIONER SPECS AND DIMENSIONS |

|||||||

|

|||||||

TECHNICAL FEATURES |

SLC 4.000 |

SLC 5.000 |

SLC 6.000 |

SLC 10.000 |

SLC 12.000 |

SLC 15.000 |

SLC 20.000 |

Maximum capacity [kg][lb] |

4.000 |

5.000 (11,000) |

6.000 (13,500) |

10.000 (22,000) |

12.000 (26,500) |

15.000 (33,000) |

20.000 (44,000) |

Ø Rotary table [mm] [inch] |

600 |

750 |

750 |

900 |

1.000 |

1.000 |

1.000 |

Maximum torque [nm] [inch-lb] |

3.500 |

4.000 |

4.000 |

7.500 |

10.000 |

10.000 |

22.000 |

OPTIONAL: - Foot switch control - Weldments support frame - Powered or manual mobile sub bases on rails - Robots integration |

|||||||

|

|